Dr Shuaifeng Hu, a postdoctoral researcher in physics at the University of Oxford, researching new thin-film perovskite materials. Image credit: Martin Small.

Dr Shuaifeng Hu, a postdoctoral researcher in physics at the University of Oxford, researching new thin-film perovskite materials. Image credit: Martin Small.

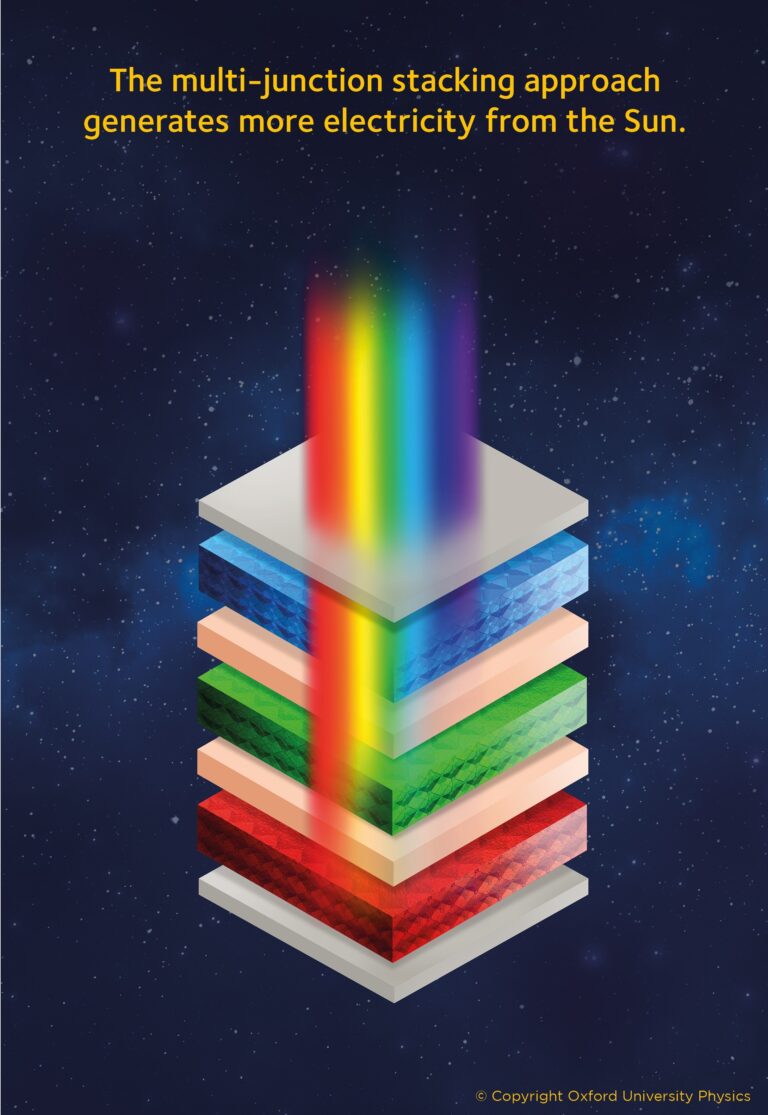

Their new light-absorbing material is, for the first time, thin and flexible enough to be applied to the surfaces of almost any building or common object. Using a pioneering technology developed in Oxford that stacks multiple light-absorbing layers into a single solar cell, it harnesses a wider spectrum of light and generates more electricity from the same amount of sunlight. Now you can.

Using this so-called multi-junction approach, the ultra-thin material has been independently certified to deliver energy efficiencies of more than 27%, matching for the first time the performance of a traditional single-layer energy-producing material known as silicon. Solar power. Japan’s National Institute of Advanced Industrial Science and Technology (AIST) granted the certification ahead of the researchers’ publication of their scientific work later this year.

“In just five years of experimenting with our stacked or multijunction approach, we have increased power conversion efficiency from about 6% to more than 27%, which is near the limit of what today’s single-layer solar power can achieve. value,” said Post’s Dr. Shuaifeng Hu. Postdoctoral fellow in physics at Oxford University. “We believe that this approach has the potential to make solar devices much more efficient than 45%.”

This compares to the energy efficiency of today’s solar panels, which is about 22% (meaning they convert about 22% of the sun’s energy), but this new ultra-thin, flexible material Versatility is also important. At just over 1 micron thick, it is almost 150 times thinner than a silicon wafer. Unlike existing photovoltaics, which are generally applied to silicon panels, this can be applied to almost any surface.

“We showed that a new material that can be applied as a coating can mimic and outperform silicon while also providing flexibility. This is important because it allows us to generate more solar power without requiring as many power plants,” said Dr Junke Wang, Marie Skłodowska-Curie-Action Postdoctoral Fellow in Physics at the University of Oxford.

The latest innovations in solar materials and technologies demonstrated in our lab are a new way to create materials that use existing buildings, vehicles, and objects to produce solar energy more sustainably and cheaply. It could become an industrial platform.

Henry Snaith, Professor of Renewable Energy, Department of Physics, University of Oxford.

The researchers believe their approach will continue to reduce the cost of solar power, making it the most sustainable form of renewable energy. Since 2010, the global average cost of solar power has fallen by almost 90%, making it almost a third cheaper than electricity produced from fossil fuels. Innovation promises further cost savings, as new materials such as thin-film perovskites reduce the need for silicon panels and dedicated solar power plants.

“Perovskite coatings are envisioned to be applied to a wider variety of surfaces, such as the roofs of cars and buildings, and even the backs of mobile phones, for the purpose of cheap solar power generation. Dr. Wang added that if we can generate solar energy, we can predict that in the long term there will be less need to use silicon panels or build more solar power plants.

The researchers are among 40 scientists working on solar power, led by Henry Snaith, Professor of Renewable Energy at Oxford University’s School of Physics. Their pioneering work in solar power generation, particularly in the use of thin-film perovskites, began about 10 years ago and has benefited from a custom-built robotic laboratory.

Henry Snaith, Professor of Renewable Energy in the Department of Physics at the University of Oxford, said: Image credit: Martin Small.

Henry Snaith, Professor of Renewable Energy in the Department of Physics at the University of Oxford, said: Image credit: Martin Small.

Their research has strong commercial potential and is already beginning to be applied across the utilities, construction and automotive manufacturing industries.

Oxford PV is a British company spun out of Oxford University Physics in 2010 by co-founder and chief scientific officer Professor Henry Snaith, with the aim of commercializing perovskite solar power, and has recently established a partnership with Brandenburg an… Large-scale production of perovskite photovoltaics has begun at the Der Havel factory. , near Berlin, Germany. This is the world’s first mass production line for “perovskite-on-silicon” tandem solar cells.

“We were initially looking at a UK site to start manufacturing, but the government has not yet matched the financial and commercial incentives offered in other parts of Europe and the US. ” said Professor Snaith. “Until now the UK has thought about solar energy purely in terms of building new solar farms, but real growth will come from the commercialization of innovation. I really hope people pay attention to this.”

“The supply of these materials is a fast-growing new industry in the global green economy and we have shown that the UK is scientifically innovating and leading the way.”However, new incentives and Without a better path to converting this innovation into manufacturing, the UK will miss out on the opportunity to lead this new global industry,” Professor Snaith added.